How A Portable Tire Inflator Works?

Sustaining an appropriate tire pressure is essential for both safe driving and tire longevity. No matter where you are, portable tire inflators are an essential item that will always keep you ready for unexpected flat tires or pressure dips. We will examine the internal workings of portable tire inflators in this post, offering details on their parts, uses, advantages, and safety precautions. Knowing how these small devices work will enable you to handle tire maintenance procedures with confidence while driving, improving your driving experience and peace of mind.

What Is A Tire Inflator?

Air compressors that run on electricity or batteries are what portable tire inflators are. Certain variants feature a 12-volt socket that can be connected to the cigarette lighter plug in your vehicle. While some tire inflator types feature power lines that attach to your car's battery, others—known as cordless tire inflators—have rechargeable batteries.

Having a flat tire that needs to be fixed or replaced can be rather inconvenient. You can be stuck on the road if you do not have a spare tire or repair equipment. In an emergency like this, a portable tire inflator can save your life. The tire inflator can be used to maintain tires at their ideal pressure consistently.

Car air compressors and tire inflators are similar devices, but tire inflators lack the massive pressurized tank of the former and instead contain a compact electrically powered piston and cylinder that provide air pressure for the tires.

Air Compressor:

The small yet strong air compressors found in portable tire inflators provide the air pressure required to inflate tires. There are two primary types of these compressors: diaphragm and piston. While diaphragm compressors employ a flexible membrane to accomplish the same goal, piston compressors use a piston-driven device to pressurize air. These compressors, no matter what kind, operate by taking in air and compressing it to the required pressure.

Power Source:

Batteries or electricity can be used to power portable tire inflators. One benefit of battery-powered inflators is their true portability, which lets you use them anywhere without having to find a power source. Conversely, electric-powered inflators require a power source to function, but they frequently offer more power and efficiency, which qualifies them for more demanding inflation jobs.

Hose and Nozzle:

Important parts that join the inflator to the tire valve are the hose and nozzle. When inflating tires, these parts provide simple maneuverability and a tight seal because of their flexibility and durability. Strong materials like rubber or reinforced nylon are used to make high-quality hoses and nozzles, guaranteeing their ability to endure repeated use.

Tire inflators differ from basic air pumps; they're compact air compressors. Understanding their workings involves dissecting their key components and how they collaborate to inflate tires.

Power Source Options

Portable tire inflators commonly connect to a wall outlet, car's 12V socket, or operate on batteries. Each has its advantages, but the 12V plug-in type is most versatile.

Switch Mechanism

Whether a dial, slider, toggle, trigger, or button, the switch completes the power circuit, activating the motor to power the device on and off.

Electric Motor

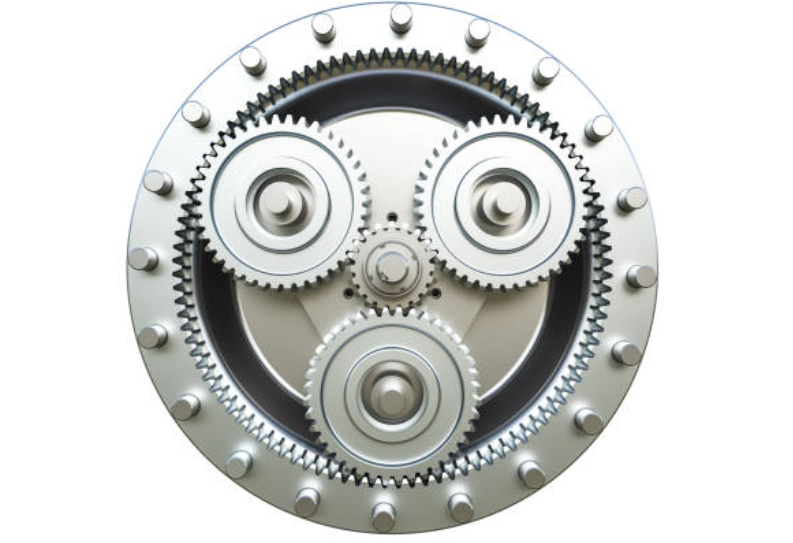

The internal electric motor is the inflator's powerhouse, driving gears that transfer energy to the piston, sometimes also cooling the device with a connected fan.

Gears

Most inflators contain two gears—one linked to the motor and another to the piston—driving piston movement. Some models may have an additional gear for fan operation.

Piston and Cylinder

Analogous to a gas-powered vehicle, the piston and cylinder execute compression. As the gears turn, the piston draws air into the cylinder, compressing it and directing it to the tire.

Fan Cooling

Typically, tire inflators integrate a fan for air-cooling, usually positioned near the motor to dissipate generated heat.

Valves

Essential valves regulate air intake and prevent backflow during piston operation, ensuring efficient compression.

Pressure Sensor

Certain inflators employ pressure sensors to gauge tire pressure for display or regulate automatic valve closure.

Connector

The tubing at the inflator's end couples it to the tire or other objects for inflation, often featuring interchangeable tips for diverse applications.

Regular Maintenance: To guarantee optimum performance and longevity, keep your portable tire inflator clean and well-maintained.

Appropriate Storage: To avoid damage and corrosion, keep your inflator out of direct sunlight and dampness. Instead, store it in a cool, dry location.

Safety measures: To prevent overloading circuits, overheating, or inflator or tire damage, abide by manufacturer guidelines and safety measures. The inflator should only be used on a sturdy surface and kept away from flammable materials.

How long can tire inflators operate?

Tire inflators contain motors that can rapidly generate heat, and insufficient cooling may limit their operational duration. Typically, these devices have run times ranging from approximately 5 to 10 minutes, although specific durations vary among inflator models. It's advisable to refer to the owner’s manual or service manual for precise operational guidelines.

Do tire inflators require oil?

While there may be exceptions, the majority of tire inflators, particularly newer models, operate without the need for oil lubrication.

Is it possible to use pneumatic tools with a tire inflator?

An air compressor that can reliably generate high pressure and sustain a constant airflow for lengthy periods of time is required for pneumatic tools. Small tire inflators are not ideal for powering pneumatic equipment because of their size and capacity, which prevents them from meeting these requirements.

What air compressor size is suitable for operating pneumatic tools?

The tasks that are intended to be performed, the available funds, and the particular pneumatic tools being used all influence the proper size of air compressor. See our full explanation on how garage air compressors work and figuring out the perfect size for thorough instructions on choosing the ideal air compressor size for your requirements.

For reasons of safety and fuel economy, tire pressure needs to be maintained. Proper tire pressure contributes to extended tire life and uniform wear. When a tire is inflated correctly, it will grip the road surface during braking, cornering, and acceleration, giving the driver confidence. Additionally, it lessens the possibility of a tire blowout while driving.

Click on the following link to read another blog post: What Is Flex Fuel?