How Garage Air Compressors Work?

When you are starting your first garage, the advice to get an air compressor may seem like just one more voice in the din of recommendations. It makes sense to feel overburdened. Past the annoyance of being pushed toward yet another large expenditure during a time already marked by cash outflows is the frustration of unclear direction. The choice of whether to get an air compressor and whether it is actually necessary for your needs are still unclear.

This ambiguity stems from the fact that air compressors are not a one-size-fits-all solution. The diversity in the usage of pneumatic tools, driven by the varied projects enthusiasts undertake, directly influences the type of compressor that best suits an individual's requirements. For instance, the compressor that revitalizes a classic car with a fresh coat of paint is distinctly different from the one used by a hobbyist engaging in occasional tinkering. Keep reading this blog post to uncover the intricacies of how garage air compressors operate, ensuring you make an informed decision that aligns perfectly with your project needs and aspirations.

Understanding Air Compressors

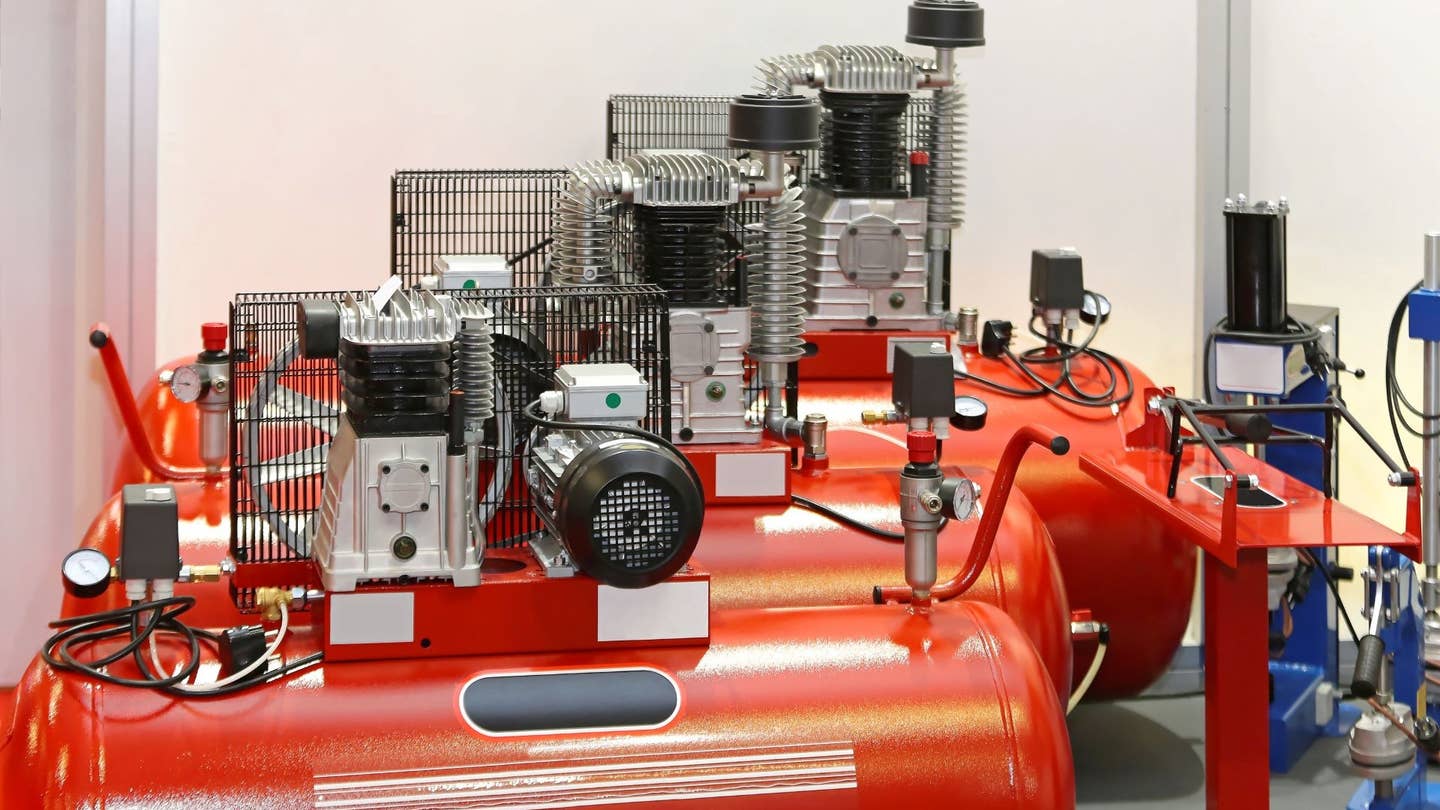

The principle of compressed air is quite remarkable. By enhancing the pressure of air and integrating it with a mechanism designed to utilize this power, air transforms into a potent source of energy for operating a variety of tools. Pneumatic tools, however, demand significantly more pressure than a basic air pump can supply. This necessity gives rise to the shop air compressor, a powerful fusion of two distinct systems into one effective unit.

At its core, a shop air compressor comprises an air pump and a storage tank. The pump's role is to draw in atmospheric air and forcefully compress it into the tank, thereby accumulating the pressure required to drive your pneumatic tools. Although the operation seems straightforward, there are key factors to consider in its functionality.

Before going any further, though, it is important to discuss the three primary pump types that are present in shop air compressors. Knowing what kind of pump a compressor is using is important since it provides information about the compressor's performance capabilities.

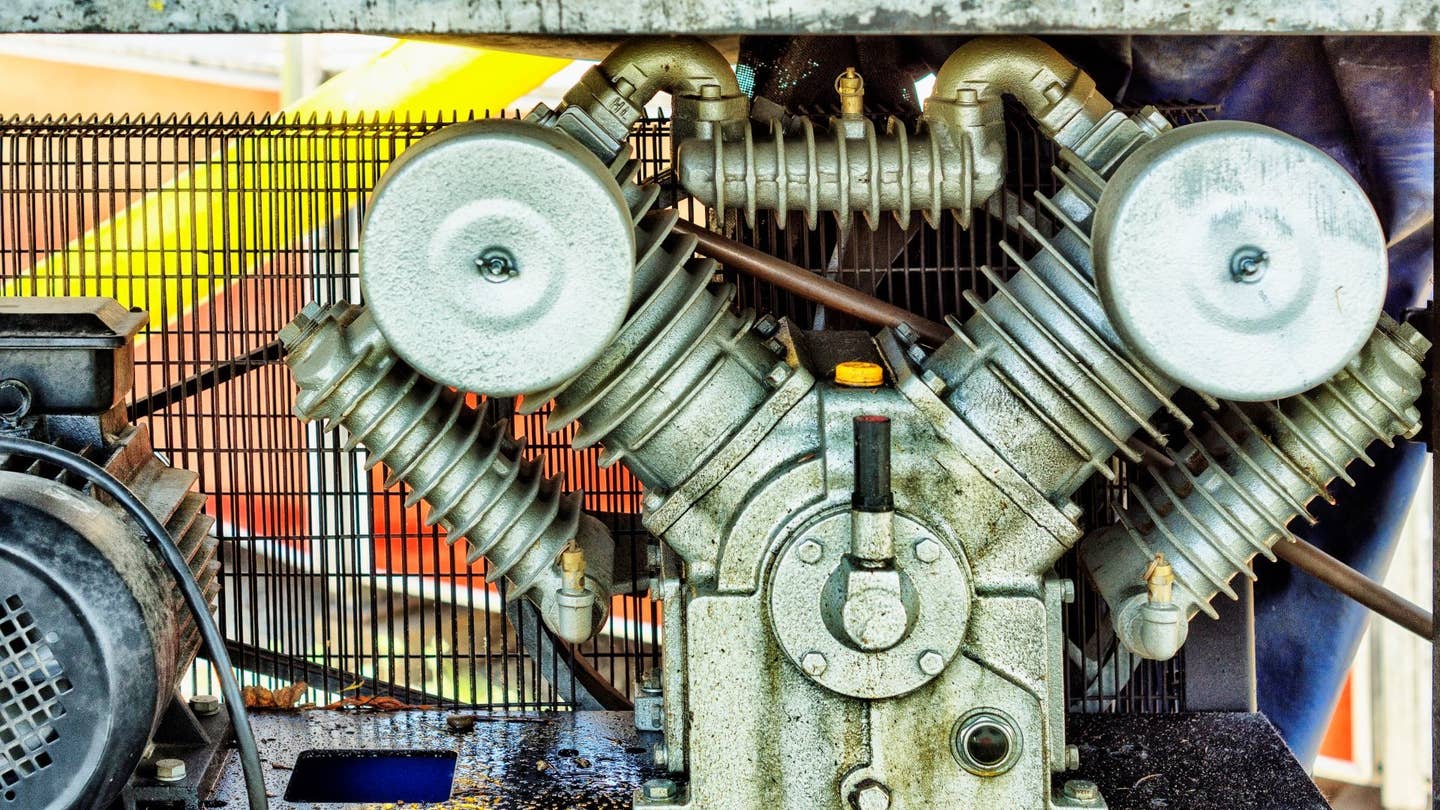

Reciprocating Pumps

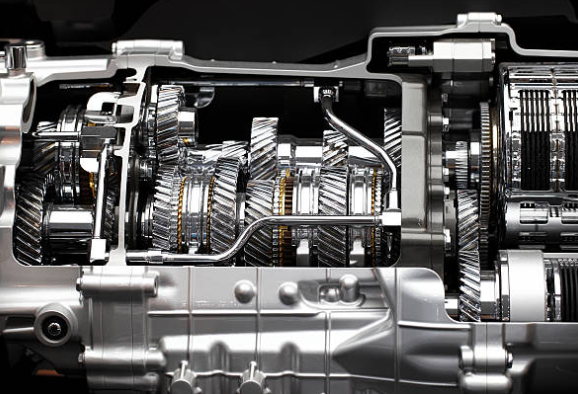

The reciprocating pump is the most basic type of compressor pump. It has a single piston that, on the intake stroke, draws air in through an inlet valve and, on the compression stroke, releases it into the tank through an outlet valve. Because this system functions similarly to an automobile engine, it may sound familiar.

Multistage Pumps

Multistage pumps represent an advanced iteration of the reciprocating pump, distinguished primarily by the inclusion of two pistons instead of one. The intriguing part is that the second piston doesn't serve to intake more air but is smaller and functions to cool the air. Cooling the air increases its density, enabling the system to achieve higher pressure levels within the tank.

Rotary Screw Pumps

Rotary screw pumps pull in air and compress it using two interlocking screws. A rotary screw pump's mechanism may remind those familiar with automobile superchargers of a twin-screw supercharger. Its cooler, quieter operation and less wear make it an excellent choice for continuous usage applications, even though it may not generate as much pressure as the reciprocating type.

It's well understood that air compressors are pivotal for powering pneumatic tools. For instance, painters are well aware of the necessity of a compressor to efficiently apply coatings. However, the necessity of an air compressor might not be as evident if your interest lies in tools that have electric alternatives.

So, is an air compressor essential for you? Let's not beat around the bush. If you're not specifically looking into tools that require compressed air, or if you're not in a professional setting that demands such tools, then strictly speaking, you don't need one.

Pneumatic tools boast considerable advantages: they are robust, lightweight, durable, and offer adjustable power output based on the air flow you provide them. In comparison to electric tools, they often deliver superior performance in terms of speed, strength, and weight. Yet, it's important to recognize that electric tools are narrowing this performance gap, and pneumatic tools come with their own set of drawbacks. They require a constant connection to an air line, come with a higher initial cost, and may not be as frequently used if you're more comfortable with electric tools.

From a personal perspective? Owning a car suggests a need for an air compressor, primarily for tire inflation. This view might seem subjective, but if you're considering a compressor for tire maintenance, why not explore options that could also enhance your tool collection?

Two distinct measures of air flow and pressure are represented by the terms CFM (cubic feet per minute) and PSI (pounds per square inch), respectively. While PSI measures the force of the air, or how strongly it is being pushed, CFM measures the volume of air flow, or simply how much air is moving. It is important to realize that various measures describe different qualities even though they may progress linearly.

Navigating the maze to find the appropriate compressor size can feel like an adventure into uncharted territory. The key starting point in this quest is identifying the tools you plan to use. This is precisely why you might not get a straightforward answer when querying about the ideal compressor size—it demands a bit of preliminary research on your part.

While it's tempting to focus primarily on tank size during your search, it's not the first attribute you should hone in on. Instead, the pressure and CFM (cubic feet per minute) capabilities of the compressor take precedence. In a typical shop environment, you might find yourself working with larger tools that require substantial air flow at higher pressures. A common requirement might be around 120 PSI and 10 CFM, so targeting systems that can meet or exceed these specifications is essential.

Tank size, contrary to some beliefs, is also a critical factor but in a different way. It's directly related to the duration the compressor can operate before needing to pause and recharge the tank. Underestimating the importance of tank size could lead to frequent interruptions and decreased efficiency. While you don't necessarily need a behemoth of a compressor for a home garage, a minimum of a 20-gallon tank is advisable.

Opting for a compressor that's a notch above what you currently think you need is also wise. Your collection of pneumatic tools is likely to expand, and purchasing a compressor that barely meets your current needs might mean you'll outgrow it sooner than later. Investing in a slightly larger or more potent unit now could save you from needing an upgrade prematurely.

Here's a snapshot of some air tools that could enrich your toolkit when powered by a suitable compressor:

- Impact Wrench and Ratchet: Say goodbye to the days of wrestling with stubborn nuts and bolts. These tools are designed to make light work of such challenges.

- Air Hammer: Channel the power of Thor without the physical exertion. An air hammer brings formidable force, all without you breaking a sweat.

- Angle Grinder: Whether it's cutting, sanding, or machining, an angle grinder is versatile enough to tackle various materials, especially metal.

- Air Blow Gun: Ideal for cleaning out dust, debris, or any unwanted material from spaces like engine bays, ensuring a clean work area.

- Compressed air has been used by humans for a very long time. Some accounts date the invention of the first bellows for metal forging to 5,000 B.C. in Europe during the middle ages.

- George Medhurst created the first motorized air compressor in 1799; it was mostly utilized in the mining sector and significantly advanced a number of other industrial domains.

- Because water from compressed air can build up and cause performance problems and corrosion over time, air compressor tanks need to be emptied on a regular basis.

- Pneumatic instruments such as the drill (1871) and hammer (1890) were not invented until almost a century after the introduction of air compressors in the late 18th century.

- Because of the process of compression, compressed air produces a lot of heat, so the system usually needs a cooling mechanism to control the high temperatures.

What does "duty cycle" mean for an air compressor?

Duty cycle is the amount of time that a compressor can run for in order to prevent damage or overheating. For example, if it has a 50% duty cycle for ten minutes, it can run for five minutes before needing to rest.

Do air compressors consume a lot of power?

Yes, they do consume a considerable amount of electricity, although not as much as electric tools. However, the impact on your electricity bill, especially for home use, is generally minimal.

Is it okay to leave air in my compressor after use?

Yes, leaving air in the compressor is fine and won't harm the system. However, leaving it can lead to more water accumulating inside the tank than if it were emptied regularly.

How long does an air compressor typically last?

Air compressors can last between 10 and 15 years, potentially longer with minimal use and proper maintenance. Lifespan can extend significantly in a home shop compared to an industrial setting.

In summary, air compressors are indispensable instruments in a wide range of sectors and have a long and illustrious history. Making educated judgments requires having a thorough understanding of how they operate, from duty cycles to CFM and PSI. Recall that despite the fact that they need maintenance and use electricity, their durability and adaptability make them worthwhile investments for any workshop.

Click on the following link top read another blog post: How To Prepare RV For Off Grid?