What Is Engine Displacement?

You will hear terms like liters, ccs, and—my personal favorite — cubic inches when people discuss engines. All of these names refer to the displacement of an engine, even if they are based on various measurement increments.

Engine displacement is significant in the powersports and automotive industries. It not only helps us gauge the power an engine can produce, but it also serves as the ultimate ego boost. Let us be honest. Bigger is usually preferable, right? Not really.

In actuality, engine displacement is merely a measurement and ultimately has very little bearing on actual performance. It is another thing entirely to comprehend that, how it functions, and why it matters now. To help you comprehend engine displacement and what it implies for performance, The Drive's engine experts are on hand.

Understanding Engine Displacement

In essence, an engine is an air pump. Although it is moving air, the design depends on the engine's capacity to displace a specific volume of air in order to mix it with fuel, ignite, and generate power. The amount of air that an engine can move is measured in terms like 426 cubic inches, 5.7 liters, and 250 cubic centimeters (cc). They are merely alternative ways of expressing the same concept: displacement.

If you are familiar with engine cycles, you are aware that a piston powered by the crankshaft is used by engines to displace air. During the intake stroke, air is drawn in, and during the exhaust stroke, air is pushed out. The amount of air that the engine can move is determined by the area of the pistons, their displacement within the cylinder, and the number of cylinders.

Improving engine displacement is a fantastic method to raise power capacity. An engine can burn more gasoline and produce more power if it can move more air. Even while it sounds amazing, basing all of your efforts on an engine's size can be disastrous. It is evident from history how accurate that is.

Consider the Fiat S76 as an instance. Known as the Beast of Turin, this vehicle shocked everyone in 1910 when it debuted with a massive 28.4-liter engine. The approximately 300 horsepower it produced is undeniably unimpressive by today's standards, even if I have nothing but respect for the historical impact it left behind. Heck, the 2.5-liter engine in the 2021 Kia Stinger is capable of producing 300 horsepower.

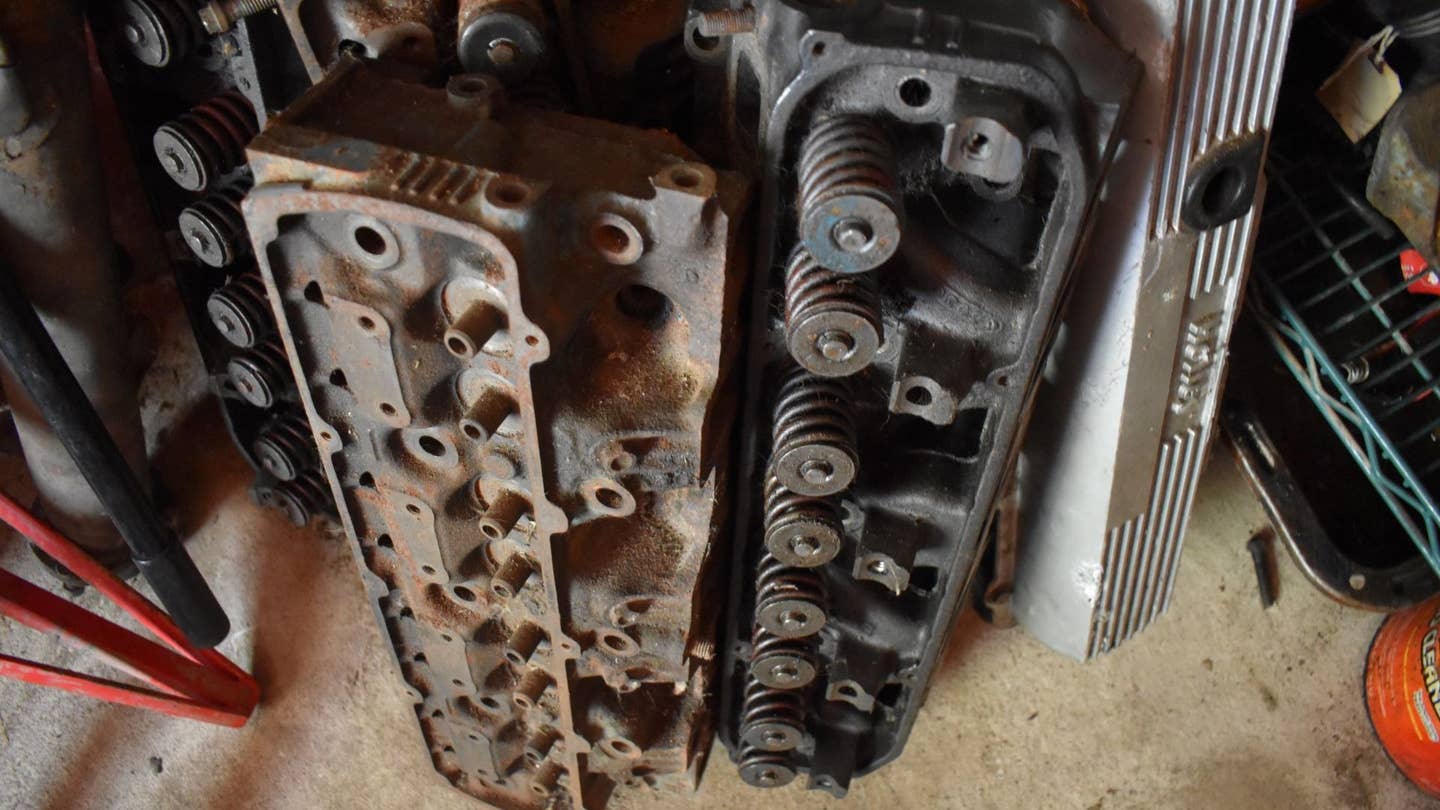

In order to demonstrate this concept, let us examine America's beloved Chevy 350 V-8. This engine produced 300 horsepower in 1970, during the height of the horsepower wars. When fuel economy and emissions rules became paramount in the mid-1980s, people had to put in a lot of work to produce the meager 175 horsepower in that generation of Chevy 350s.

How on earth could this kind of thing occur? Not to belittle the engineers working to rescue the world, but the cylinder heads and camshafts they employed destroyed the power potential of once-dominant platforms. Another significant factor contributing to power shortages was often lower compression ratios.

In the end, there are other factors to take into account besides the engine's maximum airflow capacity. An engine may not necessarily move a ton of air just because it can. Furthermore, it does not imply that an effective burn is being achieved in order to propel the pistons through the bores with any kind of force. An engine can not maximize its displacement unless it has the right camshaft, cylinder-head design, and compression ratio, to name a few.

Despite the historical missteps associated with blindly chasing displacement, there are still valid reasons for increasing an engine's displacement. Overboring cylinders and altering stroke length are two primary methods employed to achieve this. Overboring widens the cylinder bores, while increasing stroke length extends the distance traveled by the piston. Combining both methods can lead to significant displacement gains, but careful consideration must be given to factors like piston position, clearance, and overall engine compatibility.

Beyond increasing displacement, other avenues exist for enhancing engine power. Upgrading cylinder heads, camshafts, and adjusting compression ratios are common strategies, but their effectiveness depends on the specific goals and constraints of the application. Additionally, the adoption of power adders such as superchargers or turbochargers can dramatically improve an engine's performance by maximizing volumetric efficiency.

Understanding the terminology associated with engine displacement is essential for enthusiasts and professionals alike:

- Bore: The diameter of the engine's cylinder.

- Stroke: The distance traveled by the piston within the cylinder.

- Piston: The component responsible for various functions within the engine.

- Crankshaft: The shaft that converts the reciprocating motion of the pistons into rotational motion.

- Connecting Rod: Links the piston to the crankshaft, facilitating power transfer.

How does engine displacement affect performance?**

It influences an engine's potential power output, but other factors such as internal components also play significant roles.

Which is better, a short stroke or long stroke?

It depends on the desired characteristics and goals of the engine.

How is compression ratio calculated?

It involves various factors such as combustion chamber volume and piston dimensions.

How do I determine my bore size?

Methods include internet research and physical measurements using specialized tools.

What's the most common displacement for cars?

In modern times, the average displacement is around 2.0 liters, showcasing the efficiency and power of contemporary engine designs.

While engine displacement remains a fundamental metric in assessing an engine's capacity, it's just one piece of the performance puzzle. The evolution of engine technology has shown that smaller engines can deliver impressive power outputs through efficient design and optimization. Understanding the nuances of displacement, coupled with complementary modifications, empowers enthusiasts to unlock the true potential of their engines. Whether pursuing greater displacement or fine-tuning existing components, a holistic approach is essential for achieving optimal performance and driving satisfaction.

Click on the following link to read another blog post: The Ultimate Windshield Wiper Test Rig: Revolutionizing Wiper Performance

.png)