What is a Planetary Gear?

Learn all about the unique and powerful planetary gear system used in cars. We'll explain what it is, how it works, and its many advantages over other types of transmissions.

When you shop through retailer links on our site, we may earn affiliate commissions. Learn more

Have you ever pondered the seamless and consistent gear shifting in everyday machines, gadgets, and vehicles? Making this feat possible is a widely utilized technology known as planetary gears. Renowned for their versatility, planetary gears stand out among mechanical components due to their capability to enable higher torque transmission across multiple stages with fewer moving parts compared to alternative gear systems. If you're curious to delve into what planetary gears are and how they operate, continue reading!

IN THIS ARTICLE

What is a Planetary Gear?Types of Planetary Gear Systems

Applications of Planetary Gear Systems

FAQs

What is a Planetary Gear?

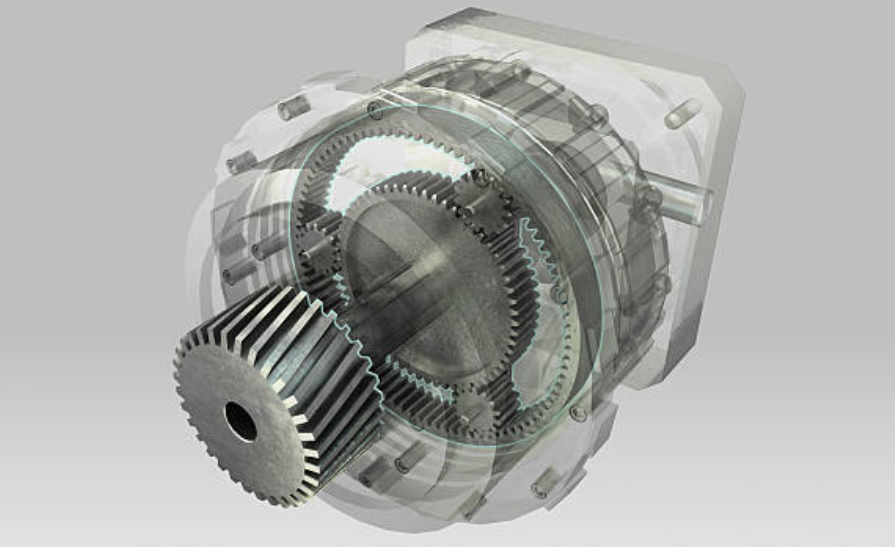

A planetary gear, or epicyclic gear, is a widely employed gear system in mechanical engineering and diverse devices. It comprises three primary components: a central sun gear, surrounding planet gears that orbit the sun gear, and an encircling ring gear that engages with the planet gears.

The unique arrangement of these gears allows for versatile and complex gear ratios, making planetary gears suitable for a wide range of applications. The term "planetary" comes from the way the planet gears move in orbit around the central sun gear, resembling the motion of planets orbiting the sun.

Planetary gears offer several advantages, including compact design, high torque transmission capabilities, and efficiency in various speed applications. They are commonly found in automatic transmissions in vehicles, watches, bicycles, robotics, and many other mechanical systems where controlled and efficient speed variations are essential.

Related Articles

Types of Planetary Gear Systems

Simple Planetary Gear System:

- Consists of a central sun gear, an outer ring gear (annulus), and one or more planet gears.

- The planet gears rotate around the sun gear and are also meshed with the outer ring gear.

- This configuration allows for speed reduction, torque amplification, or direction reversal.

Compound Planetary Gear System:

- Combines multiple sets of simple planetary gear systems within a single gearbox.

- The output of one planetary gearset becomes the input for the next, allowing for increased gear ratio options.

Ravigneaux Gear System:

- A type of compound planetary gear system with two sun gears, a single planet carrier, and two sets of planet gears.

- Used in automatic transmissions for vehicles.

Simpson Gear System:

- Similar to the Ravigneaux system but has a different arrangement of gears.

- Commonly used in automatic transmissions.

Sun and Planet Gear System:

- Features multiple sun gears and planet gears without an outer ring gear.

- Used in clock mechanisms and some automatic transmissions.

Harmonic Drive System:

- Utilizes a flexible, wave-like structure to achieve high gear reduction ratios in a compact space.

- Commonly used in robotics and precision machinery.

Cycloidal Drive System:

- Employs eccentric cam mechanisms to achieve motion.

- Provides high torque and precision motion control.

- Used in robotics, automation, and industrial machinery.

Differential Planetary Gear System:

- Combines planetary gears with a differential mechanism.

- Allows for torque distribution between two output shafts, commonly found in automotive differentials.

Torque Split Planetary Gear System:

- Used in hybrid vehicles to split and distribute torque between the internal combustion engine and an electric motor.

Planetary Roller Screw System:

- Combines planetary gears with a roller screw mechanism.

- Transforms rotary motion into linear motion with high efficiency.

- Used in various linear actuator applications.

Applications of Planetary Gear Systems

Planetary gear systems, also known as epicyclic gears, have become integral components in numerous industries, showcasing their adaptability and efficiency. In the automotive sector, they play a pivotal role in automatic transmissions, ensuring smooth and precise gear shifts.

The renewable energy landscape benefits from planetary gears in wind turbines and solar trackers, optimizing energy production. In aerospace applications, such as aircraft landing gear systems and satellites, these gears offer reliability and space-efficient solutions. From robotic systems requiring precise movement to the construction equipment handling heavy loads, planetary gears prove their versatility.

Even everyday items like bicycles and timekeeping devices, such as clocks and watches, benefit from their compact and reliable design. With applications ranging from medical devices to mining equipment, the adaptability of planetary gear systems underscores their significance across a wide spectrum of industries, contributing to enhanced functionality and performance in diverse mechanical systems.

FAQs

-

Can planetary gears be used in robotics?

Yes, planetary gears are commonly used in robotics to provide precise and controlled movement in robotic arms, joints, and other mechanical components.

-

Are planetary gears suitable for high-speed applications?

Yes, planetary gears are well-suited for high-speed applications due to their efficient power transmission capabilities and compact design. They are often employed in various high-speed machinery and systems.

View more article here: Top 10 Electric Scooter Street Legal For Adults