How To Use A Fluid Transfer Pump?

Fluid transfer pumps are indispensable tools in various settings, from automotive maintenance to household chores and industrial applications. Imagine needing to transfer fuel from a storage container to your vehicle or emptying a clogged sink without the hassle of manual scooping. A fluid transfer pump can make these tasks effortless and efficient.

In this guide, we'll walk you through everything you need to know about using a fluid transfer pump effectively and safely.

What Is A Fluid Transfer Pump?

A fluid transfer pump is a device designed to move liquids from one container to another. These pumps come in various types and sizes, each suited for specific tasks. Whether you need to transfer fuel, water, oil, or other liquids, there's likely a pump designed for your needs.

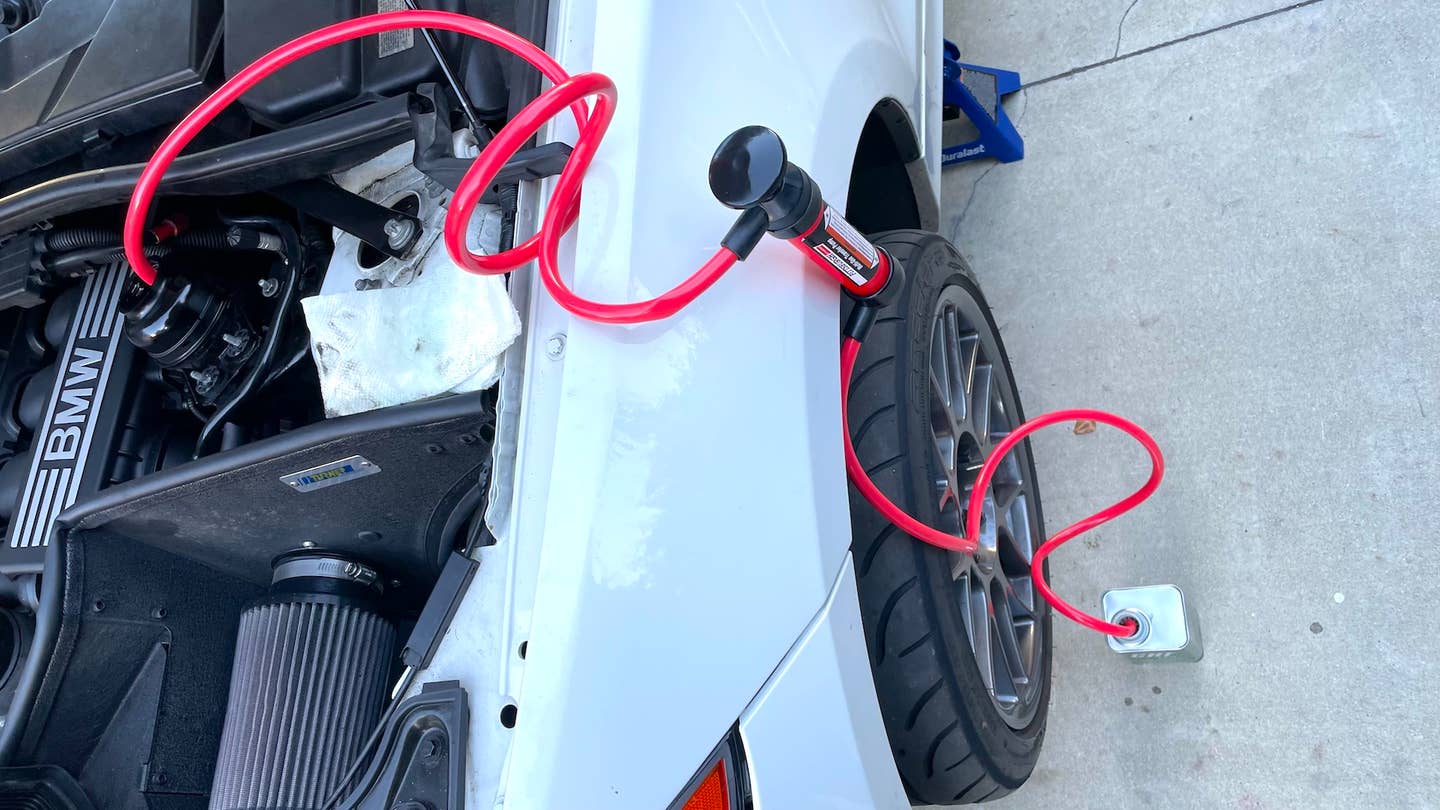

Manual Pumps

Manual pumps are operated by hand, making them perfect for small-scale jobs where electric power isn't available. They're simple to use, portable, and typically less expensive. However, they require more physical effort and are not ideal for large volumes of fluid.

Electric Pumps

Electric pumps are powered by electricity and are suitable for medium- to large-scale fluid transfers. They are more efficient and faster than manual pumps, making them ideal for tasks that involve substantial amounts of liquid. The downside is that they need a power source, which can limit their portability.

Pneumatic Pumps

Pneumatic pumps use compressed air to move fluids and are often used in industrial settings. They are powerful and can handle a wide range of fluids, including viscous liquids. However, they require an air compressor and are generally more expensive.

Safety Precautions

Before you start, it's crucial to prioritize safety. Always read the pump's manual to understand its specific requirements and limitations. Wear appropriate personal protective equipment (PPE), such as gloves and safety goggles, to protect yourself from spills and splashes.

Tools and Materials Needed

Gather all necessary tools and materials:

- The fluid transfer pump

- Hoses and connectors

- Source and destination containers

- Cleaning supplies

- PPE

- Inspecting the Pump

Check the pump for any signs of damage or wear. Ensure that all parts are clean and functioning correctly. This step can prevent potential issues during the transfer process.

1. Setting Up the Pump

Choose the right pump based on the type and volume of the fluid. Assemble the pump if necessary, following the manufacturer's instructions. Attach hoses and connectors securely to avoid leaks.

2. Preparing the Source and Destination Containers

Ensure that both the source and destination containers are clean and suitable for the fluid. Position them in a stable manner to prevent tipping or spillage during the transfer.

3. Operating the Pump

- Manual Pump Operation

- Insert the intake hose into the source container and the discharge hose into the destination container.

- Start pumping manually, using a hand lever or bulb. Keep a steady rhythm to maintain a consistent flow.

- Monitor the fluid level to avoid overflows.

- Electric pump operation

- Connect the pump to a power source.

- Insert the hoses into the respective containers.

- Turn on the pump and adjust any settings if necessary.

- Keep an eye on the fluid levels and flow rate, adjusting as needed.

- Pneumatic Pump Operation

- Connect the pump to an air supply.

- Insert the hoses into the containers.

- Operate the controls to start the fluid transfer.

- Monitor the process to ensure smooth operation.

4. Monitoring the Transfer

Stay vigilant during the transfer to prevent overflows and spills. Adjust the flow rate if necessary, and ensure the pump is running smoothly without any unusual noises or vibrations.

Cleaning the pump

After use, safely dispose of any residual fluid in the pump. Clean the pump thoroughly to prevent contamination and buildup. Use appropriate cleaning solutions based on the type of fluid transferred.

Storing the pump

Store the pump and its components in a dry, cool place. Proper storage ensures the longevity of the pump and keeps it ready for future use.

Can I use a fluid transfer pump for different types of fluids?

Yes, but ensure you clean the pump thoroughly between uses to avoid contamination.

How often should I maintain my fluid transfer pump?

Regular maintenance should be performed after each use, with a thorough inspection every few months.

Can I use the same fluid transfer pump for water and gasoline?

It's not recommended due to the risk of contamination and safety hazards. Ideally, use separate pumps for different fluids, especially flammable ones.

How do I know if my pump is compatible with the fluid I want to transfer?

Check the pump’s specifications and the manufacturer’s guidelines to ensure compatibility with the fluid type.

Fluid transfer pumps are essential tools for a variety of applications. By understanding the different types of pumps and following the proper procedures, you can transfer fluids safely and efficiently. Remember to prioritize safety, perform regular maintenance, and troubleshoot any issues promptly. With these guidelines, you'll be well-equipped to handle any fluid transfer task that comes your way.

Click on the following link to read another blog post: How Does A Turbo Wastegate Work?