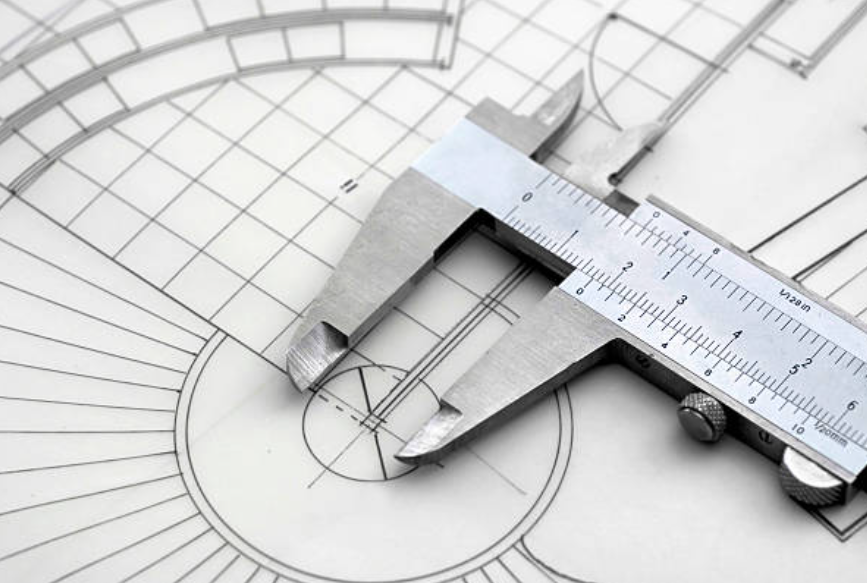

How to Read Calipers

Interpreting caliper readings might seem intimidating to beginners entering the realm of metalworking and machining. Yet, as you delve into the mechanisms and information calipers offer, these tools evolve into invaluable assets enabling precise measurements down to the minutest detail. Within this blog post, we'll embark on an intricate journey, unraveling the intricacies of deciphering caliper readings accurately.

From comprehending the multifaceted components that constitute calipers to achieving pinpoint measurements, we'll guide you step by step. By the time you conclude this article, you'll possess a confident mastery over extracting and comprehending caliper readings with the finesse of a seasoned expert!

What is Calipers?

Calipers serve as precise measuring instruments employed to ascertain an object's dimensions with remarkable accuracy. Comprising dual adjustable jaws or arms, they envelop the object, enabling meticulous measurement of its length, width, diameter, or depth. Available in diverse variants like vernier, digital, and dial calipers, each offering distinct accuracy levels and ease of use, these tools find widespread application across engineering, manufacturing, woodworking, metalworking, and scientific research domains. Their role is pivotal in guaranteeing meticulous measurements essential for tasks such as design, crafting, and quality control.

Vernier Calipers:

Characterized by a primary scale and a compact vernier scale, vernier calipers provide remarkable precision. They excel in measuring both inner and outer dimensions, including depth. With applications spanning engineering, woodworking, and metalworking, these calipers deliver meticulous measurements ideal for intricate projects.

Digital Calipers:

Digital calipers display measurements on an electronic screen in either metric or imperial units. Their ease of use and immediate readouts make them ideal for rapid measurements in fields like machining, electronics, and laboratory work.

Dial Calipers:

Dial calipers have a circular dial that displays measurements, making them suitable for applications where visual confirmation is crucial. They are often used in automotive maintenance, where the dial's face provides a clear indication of measurements.

Inside Calipers:

Referred to as internal calipers, inside calipers are utilized for gauging an object's inner dimensions, including hole diameters or the space between two surfaces. These tools are valuable in precision machining and woodworking tasks.

Outside Calipers:

Outside calipers, or external calipers, measure the outer dimensions of an object, like the width of a workpiece. They are employed in metalworking, carpentry, and engineering tasks that demand accurate outer measurements.

Divider Calipers:

Divider calipers have two pointed legs and are primarily used for marking and layout work. They can transfer dimensions between objects, making them handy for pattern making, artwork, and metal fabrication.

Hermaphrodite Calipers:

Hermaphrodite calipers combine the features of inside and outside calipers, allowing for both external and internal measurements. They are versatile tools used in various applications, such as pattern making and metalwork.

Odd Leg Calipers:

Odd leg calipers, also known as hermaphrodite calipers, consist of one straight leg and one curved leg. They are used for measuring and transferring dimensions in woodworking and metalworking, particularly in irregular or curved shapes.

Step 1: Grasping the Components

Before delving into measurements, acquaint yourself with caliper parts. From the main scale and sliding mechanism to the jaws and depth rod, comprehending their roles is pivotal for successful usage.

Step 2: Choose the Right Caliper

Select the appropriate type of caliper for your measurement needs. Vernier calipers, digital calipers, and dial calipers are common types, each offering unique advantages. Choose one that suits your preferences and the level of precision required.

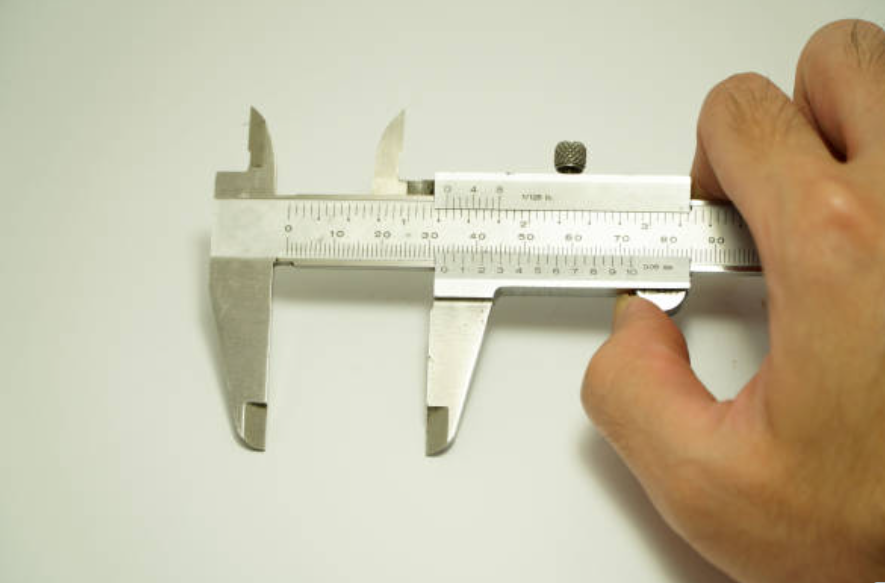

Step 3: Prepare the Caliper

Hold the caliper by the handle, ensuring it's clean and free of debris. Close the jaws and set the locking screw to prevent any movement during measurement.

Step 4: Take External Measurements

Place the object between the jaws of the caliper, ensuring a snug fit without excessive force. Read the main scale value that lines up with the left edge of the vernier scale. Next, identify the vernier scale division that aligns perfectly with a division on the main scale. This division represents the fraction of a measurement to add to the main scale reading.

Step 5: Take Internal Measurements

For internal measurements, insert the jaws into a hole or gap, and repeat the process as with external measurements. The difference here is that you'll add the vernier scale reading to the main scale value, instead of subtracting it.

Step 6: Measure Depth

To measure depth, extend the depth rod until it touches the bottom of the recess. Read the main scale and vernier scale as before, taking into account the depth rod value.

Step 7: Read the Digital Display (If Applicable)

If you're using a digital caliper, the measurement will be shown on a digital display. Take note of the value displayed, which can be in metric or imperial units based on your preference.

Step 8: Record Your Measurement

Once you've obtained an accurate measurement, record it in your desired units for future reference.

Step 9: Practice and Refine Your Skills

Reading calipers accurately takes practice. Try measuring various objects with different shapes and sizes to build your proficiency.

-

Are digital calipers more accurate than vernier calipers?

Both digital and vernier calipers can provide accurate measurements. Digital calipers offer quick readings with electronic displays, while vernier calipers require closer observation for accurate interpretation.

-

Can calipers be used for both metric and imperial measurements?

Yes, some calipers offer both metric and imperial scales, allowing you to choose the measurement system that suits your needs.

See more review here: Top 10 Interior Paints To Transform Your Space