How To Change Drum Brakes?

Replacing drum brakes is a fundamental aspect of vehicle maintenance that ensures optimal safety and performance on the road. Whether you're a seasoned DIY enthusiast or a novice looking to delve into automotive repair, understanding the process of changing drum brakes is invaluable knowledge.

This comprehensive guide will walk you through the step-by-step procedure, equipping you with the necessary skills and confidence to tackle this task effectively. By following these instructions, you'll not only enhance your understanding of your vehicle's braking system but also contribute to its longevity and reliability.

What Are Drum Brakes?

Drum brakes are a type of braking system used in cars. They work by pressing brake shoes lined with friction material against the inside of a drum-shaped housing in each wheel. This creates friction, slowing down or stopping the vehicle. Drum brakes are less common in newer cars but are still used in some vehicles, particularly in the rear wheels and heavy-duty applications.

Here are some signs indicating it might be time to change your drum brakes:

- Squealing or grinding noises: If you hear high-pitched squealing or grinding noises when you apply the brakes, it could indicate that the brake shoes are worn down and need replacement.

- Reduced Braking Performance: If you notice that your car takes longer to stop or requires more pressure on the brake pedal to stop, it might be a sign that the brake shoes are worn and need to be replaced.

- Brake Pedal Feel: If your brake pedal feels soft or spongy when you press it, it could be due to worn-out brake shoes or other brake components needing replacement.

- Uneven Braking: If your car pulls to one side when you brake, it could indicate uneven wear on the brake shoes or other brake problems that need attention.

- Visible Wear: If you inspect your drum brakes and notice that the brake shoes are worn down, cracked, or unevenly worn, it's a clear sign that they need replacement.

- Brake Warning Light: Some vehicles have a brake warning light on the dashboard that illuminates when there's a problem with the braking system. If this light comes on, it's essential to have your brakes inspected promptly.

Regular inspection and maintenance of your brake system can help you catch these signs early and ensure your safety on the road.

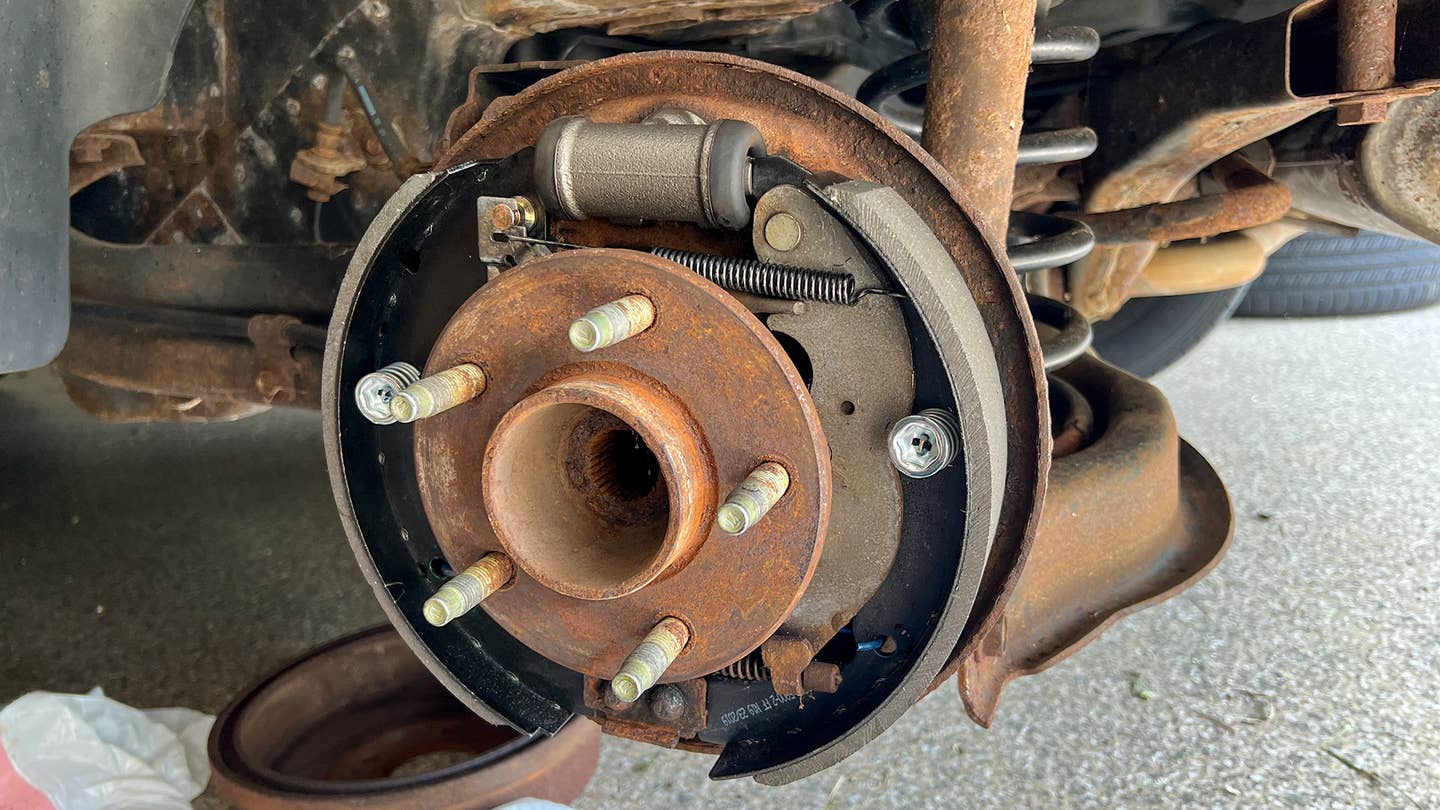

A drum brake system consists of several key components, including brake shoes, brake drum, wheel cylinder, springs, and an adjuster mechanism.

- Brake Shoes: These are curved metal plates lined with friction material (usually made of asbestos or other composite materials) that press against the inside surface of the brake drum when the brakes are applied.

- Brake Drum: This is a circular, drum-shaped component mounted on the wheel hub. When the brake pedal is pressed, the brake shoes are forced against the inside surface of the drum, creating friction and slowing down the rotation of the wheel.

- Wheel Cylinder: It's a hydraulic component that pushes the brake shoes against the drum when hydraulic pressure is applied. The cylinder is typically located at the top of the brake assembly, between the two brake shoes.

- Springs and Adjuster Mechanism: These components help to retract the brake shoes when the brakes

Changing drum brakes involves several steps and requires some mechanical skill. Here's a general guide on how to change drum brakes:

Tools and materials needed:

- Jack and Jack stand

- Lug wrench

- Brake cleaner

- Brake spring tool

- Brake-adjusting tool

- Brake grease

- Replacement brake shoes and hardware kit

- Brake fluid

Step-by-step to change drum brakes:

- Prepare the vehicle. Park the vehicle on a flat surface and engage the parking brake. Loosen the lug nuts on the wheels of the brake assembly you'll be working on.

- Lift the Vehicle: Use a jack to lift the vehicle off the ground and support it securely with jack stands. Remove the lug nuts and take off the wheel to access the brake drum.

- Remove the Drum: If the drum is stuck, use a rubber mallet to gently tap it around the edges until it comes loose. Once free, slide the drum off the wheel hub.

- Inspect and Clean: Inspect the brake components for wear, damage, or signs of overheating. Use brake cleaner to clean the brake drum, brake shoes, wheel cylinder, and other components. Be careful not to inhale brake dust.

- Remove Old Brake Shoes: Use a brake spring tool to remove the retaining springs and clips holding the brake shoes in place. Take note of how they are installed for reassembly. Remove the brake shoes from the brake assembly.

- Install New Brake Shoes: Install the new brake shoes in the reverse order of removal. Make sure they are positioned correctly and securely in place.

- Adjust the Brakes: Use a brake adjusting tool to adjust the brake shoes so they are properly aligned with the brake drum. Adjust the star wheel adjuster until there is a slight drag when spinning the drum.

- Reassemble: Reinstall the drum onto the wheel hub. Ensure it spins freely without any interference. Reinstall the wheel and lug nuts, then lower the vehicle to the ground.

- Test the brakes: Pump the brake pedal a few times to seat the brake shoes against the drum. Test the brakes by slowly applying pressure to ensure they engage properly.

- Check Brake Fluid: Check the brake fluid level in the master cylinder and top it up if necessary. Ensure there are no leaks around the wheel cylinder or brake lines.

- Repeat on the Other Side: If replacing both sets of drum brakes, repeat the process on the other side of the vehicle.

Always consult the vehicle's service manual for specific instructions and torque specifications. If you're not comfortable performing this task, it's best to seek assistance from a professional mechanic.

Is it possible to install new brake shoes on existing drums?

Yes, it's entirely feasible. Provided the drums are not extensively rusted, they can be cleaned and reused. However, if significant pitting or structural damage is observed, replacement is recommended.

How many brake shoes are typically found in a drum brake assembly?

A drum brake assembly usually comprises two brake shoes per wheel.

Is the hand brake integrated into the drum brake system?

Yes, the hand brake can be a component of the drum brake system. Detailed explanations regarding its involvement are provided in steps five and nine.

Mastering the process of changing drum brakes not only enhances your vehicle maintenance skills but also ensures safety and performance on the road. By following the steps outlined in this guide, you gain the confidence to tackle this task effectively. Regular maintenance of your vehicle's braking system is essential for its longevity and reliability. So, with the knowledge and skills you've acquired, you're equipped to take control of your vehicle's maintenance needs with precision and confidence.

Click on the following link to read another blog post: What Is The Best Way To Sell My Used Car?