How Does A Turbo Wastegate Work?

Turbochargers have revolutionized automotive performance, allowing engines to produce more power without significantly increasing their size. However, controlling the boost pressure generated by a turbocharger is crucial to maintaining engine reliability and performance. This is where the turbo wastegate comes into play.

In this post, we'll explore what a turbo wastegate is, its types, how it works, and why it is an essential component of modern turbocharged engines.

What Is A Turbo Wastegate?

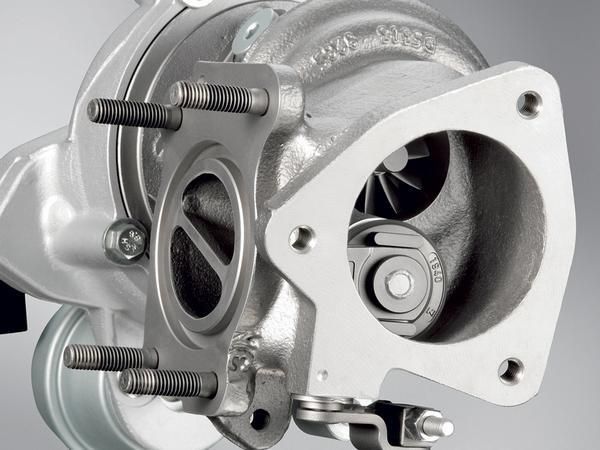

A turbo wastegate is a critical component in turbocharged engines, responsible for regulating the engine's boost pressure. The turbocharger increases the engine's efficiency and power output by forcing more air into the combustion chamber. However, without a mechanism to control this boost pressure, the engine can be subjected to excessive pressure, leading to potential damage and decreased performance. The wastegate ensures that the turbocharger operates within safe limits by diverting excess exhaust gases away from the turbine wheel, effectively controlling the boost pressure.

There are two main types of wastegates used in turbocharged engines: internal and external wastegates.

Internal Wastegates

Internal wastegates are built into the turbocharger assembly. They are simpler and more compact, making them ideal for space-constrained engine bays. An internal wastegate typically consists of a small flap inside the turbine housing that opens to divert exhaust gases when needed.

Pros:

- More compact and integrated design.

- Easier and less expensive to install.

Cons:

- Limited in flow capacity, which can be a drawback for high-performance applications.

- Less efficient at controlling boost pressure at higher levels.

External Wastegates

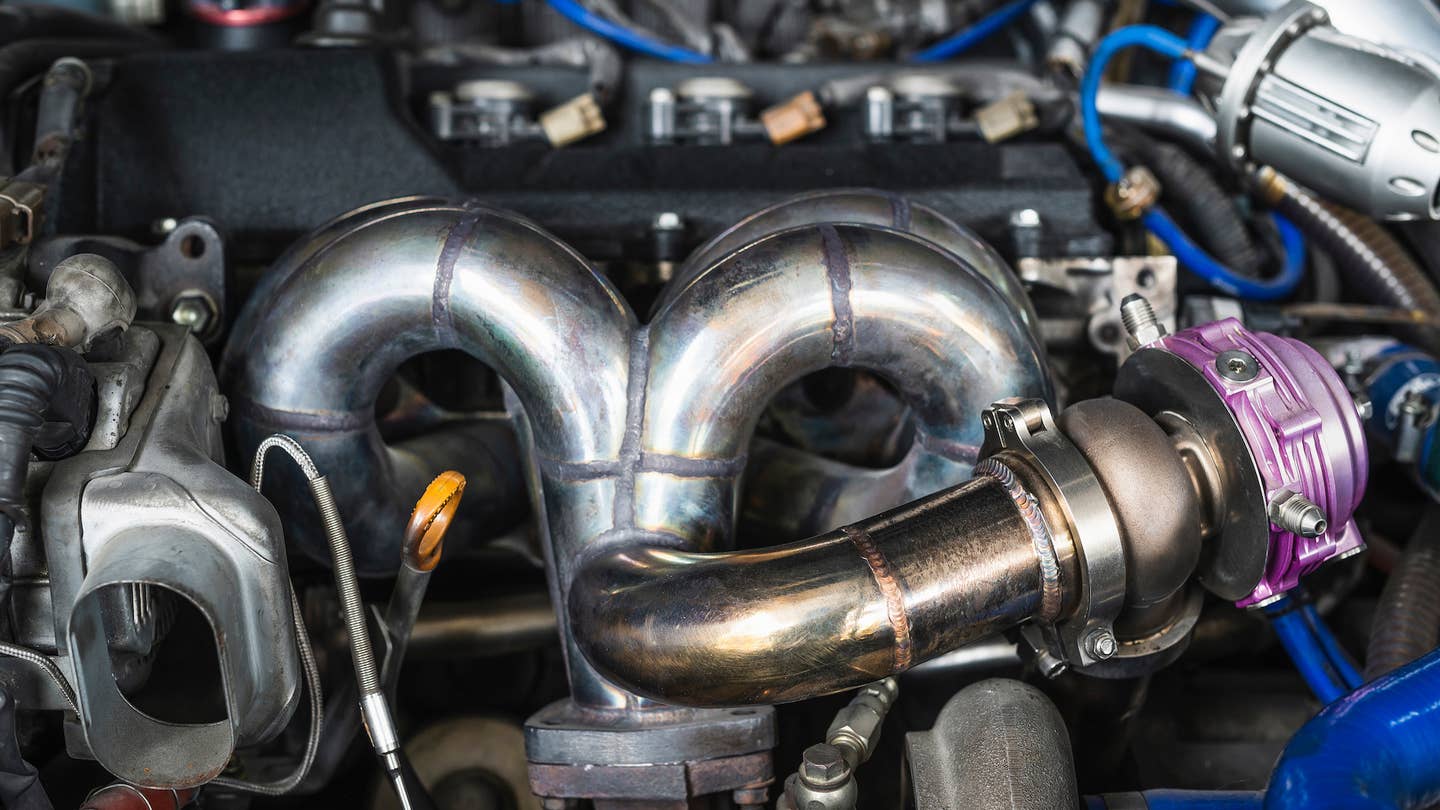

External wastegates are separate units mounted away from the turbocharger. They are connected to the exhaust manifold and the turbo via dedicated piping. External wastegates are larger and more robust, making them suitable for high-performance and high-boost applications.

Advantages:

- Greater flow capacity, allowing for better control of boost pressure at higher levels.

- More precise boost control, enhancing performance.

Scenarios Where Preferred:

- High-performance and racing applications where precise boost control is critical.

- Situations requiring higher boost levels than an internal wastegate can manage.

Comparison with Internal Wastegates: External wastegates offer superior performance and flexibility, but at a higher cost and complexity. They are often the choice for serious enthusiasts and racers looking to push their engines to the limit.

- Prevents Overboosting: By regulating the boost pressure, wastegates protect the engine from excessive pressure that could cause damage.

- Improves Performance: Ensuring optimal boost pressure helps maintain engine performance and efficiency.

- Enhances Durability: Proper boost control extends the lifespan of both the turbocharger and the engine.

- Customization: External wastegates offer greater flexibility for tuning and performance adjustments, making them ideal for enthusiasts and racers.

The operation of a turbo wastegate is relatively straightforward yet crucial for the engine's performance and longevity. Here's a step-by-step explanation:

- Boost Pressure Monitoring: As the turbocharger compresses the intake air, the boost pressure increases. A pressure source, typically from the intake manifold, is used to monitor this boost pressure.

- Actuation Mechanism: The wastegate uses an actuator, which is a diaphragm or piston connected to a spring. The actuator is connected to the wastegate valve, either internally or externally.

- Pressure Threshold: The spring inside the actuator is calibrated to a specific pressure threshold. When the boost pressure reaches this threshold, it exerts enough force on the diaphragm to compress the spring.

- Valve Opening: Once the spring is compressed, the diaphragm moves, causing the wastegate valve to open. This opening allows a portion of the exhaust gases to bypass the turbine wheel.

- Regulating Boost: By diverting exhaust gases away from the turbine, the turbocharger's speed is controlled, thereby regulating the boost pressure generated.

- Continuous Adjustment: The wastegate continuously adjusts the valve position to maintain the desired boost pressure, closing when the pressure drops below the threshold and opening when it exceeds.

1. Why is a wastegate important for turbocharged engines?

A wastegate prevents overboosting, which can lead to engine damage, ensuring the engine operates within safe pressure limits.

2. Can a wastegate affect engine performance?

Yes, a properly functioning wastegate optimizes boost pressure, enhancing performance and efficiency. Conversely, a malfunctioning wastegate can cause poor performance and potential engine damage.

3. What's the difference between an internal and external wastegate?

Internal wastegates are built into the turbocharger, while external wastegates are separate components. External wastegates offer better control and are preferred for high-performance applications.

4. Can I upgrade my car’s wastegate?

Yes, upgrading to an external wastegate can provide better boost control and performance, especially for modified or high-performance engines.

5. How do I know if my wastegate is malfunctioning?

Symptoms of a faulty wastegate include inconsistent boost pressure, loss of power, and abnormal engine noises. A professional diagnostic is recommended for an accurate assessment.

A turbo wastegate is an essential component in turbocharged engines, ensuring the right balance between performance and safety. By regulating boost pressure, it prevents potential engine damage and maintains optimal performance. Whether you have a factory-installed internal wastegate or a high-performance external one, understanding how this component works can help you appreciate the engineering behind your turbocharged engine. For enthusiasts and racers, choosing the right wastegate and maintaining it properly can make a significant difference in achieving peak performance and reliability.

Click on the following link to read another blog post: How To Use A Fluid Transfer Pump?