How Are Seat Belts Tested for Your Safety?

Have you ever pondered the meticulous testing procedures that seat belts undergo before they find their place in your car? Often, we take the benefits of a properly functioning seat belt for granted, failing to recognize its vital role in safeguarding us. Yet, concealed within every safety latch lies a sophisticated engineering process governed by stringent regulations, all designed to assure your protection against potential impacts.

We will delve into the rigorous testing protocols that seat belts are subjected to in order to guarantee their performance and reliability. We'll explore how crash simulations replicate real-world collisions, the universal automotive standards that must be met, and the intricate development process behind these life-preserving technologies. You'll gain a deeper understanding of how even the smallest details can have a profound impact on ensuring our safety on roads across the globe.

Overview of Safety Regulations for Seat Belts

In the domain of vehicle safety, a thorough structure of regulations and directives dictates the design and effectiveness of seat belts. The National Highway Traffic Safety Administration (NHTSA), especially through the implementation of Federal Motor Vehicle Safety Standard (FMVSS) No. 208, is largely responsible for assuring compliance with these regulations inside the United States.

This standard meticulously delineates the requirements for seat belt assembly and enforces clear, user-friendly labeling. It covers aspects such as load capacity, strength, and anchorage points. Internationally, the adoption of three-point seat belts, combining lap and shoulder restraints, is a recognized requirement for vehicles to enhance collision protection.

Child restraint systems are subject to stringent regulations to ensure the safety of young passengers, emphasizing proper installation and compatibility. Manufacturers must rigorously crash-test seat belts in dynamic and static scenarios to validate their effectiveness. Seat belts are labeled with essential information and certifications from relevant authorities to guarantee compliance.

Additionally, seat belts are subjected to sled tests replicating real-world collisions to evaluate their performance under various conditions. Retractor systems are engineered to maintain tension, quick-release mechanisms facilitate swift emergency exits, and universal compatibility ensures broad usability. Continuous compliance and rigorous testing procedures by manufacturers are paramount to preserving seat belt safety standards, thus contributing to enhanced road safety for all.

1. Crash Test Dummies: Simulating Real-Life Scenarios

Crash test dummies are a crucial part of seat belt testing. These lifelike dummies come in various sizes to simulate the diverse range of passengers in a vehicle, from adults to children. They are equipped with sensors to measure the forces exerted on different body parts during a crash.

2. High-Speed Impact Testing: Pushing the Limits

Seat belts are subjected to high-speed impact testing to mimic real-life collision scenarios. Vehicles are crashed into walls or other objects at varying speeds to assess how seat belts restrain occupants during accidents. The goal is to ensure that passengers are held securely in place, minimizing the risk of injury.

3. Dynamic Testing: The Jerk and Pull

Dynamic testing involves simulating sudden stops and jerks, as well as rollover scenarios. Seat belts are put through rigorous pulling and jerking to evaluate their strength and ability to hold passengers securely in place when subjected to unexpected forces.

4. Accelerated Aging Tests: Longevity Matters

Seat belts are exposed to harsh conditions and extreme temperatures to assess their durability over time. This ensures that seat belts remain reliable throughout their lifespan, even after years of use and exposure to environmental factors.

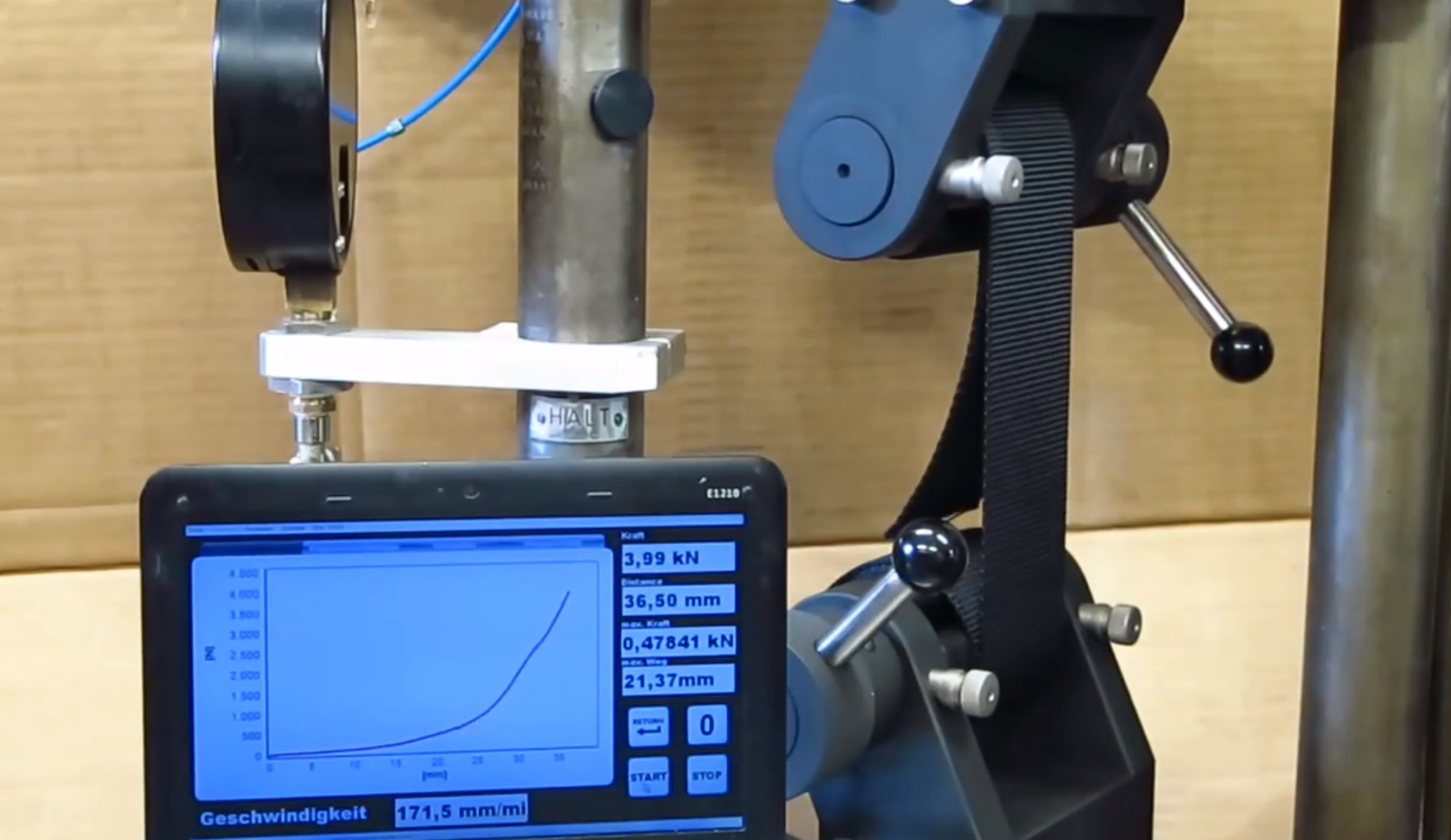

5. Load Testing: Weight and Resistance

Load testing is performed to determine how much weight a seat belt can withstand. Manufacturers test seat belts to ensure they can handle the force of impact without breaking or stretching beyond their design limits.

6. Quality Control and Certification: Meeting Safety Standards

Seat belts are required to adhere to rigorous safety standards and regulations established by organizations such as the National Highway Traffic Safety Administration (NHTSA). Manufacturers implement stringent quality control measures and pursue certification to guarantee their compliance with these safety standards.

7. Real-Life Crash Data Analysis: Continuous Improvement

Manufacturers often analyze real-life crash data to improve seat belt design and performance. By studying actual accident scenarios, they can make adjustments to enhance the safety and effectiveness of seat belts.

It is frequently these apparently insignificant factors that delineate a secure environment from one fraught with potential dangers. Whether we're discussing the construction of a seat belt or the planning of a traffic sign, these inconspicuous elements play a pivotal role in preserving lives.

Consider for example, the meticulous stitching on a safety harness; each thread contributes to its overall strength and reliability. Similarly, the reflective paint used on road markings ensures visibility in low-light conditions, reducing the likelihood of accidents. These small yet critical intricacies permeate various facets of our lives, from the effectiveness of a smoke detector's sensor to the precision of an aircraft's instrument panel.

Safety, without a doubt, hinges on these intricate details, often determining whether we return home unscathed or encounter potential hazards. As we navigate our daily routines, it's imperative to recognize and value the significance of these seemingly minor aspects in safeguarding our well-being.

-

How often are seat belts retested for safety?

Seat belt manufacturers continually test and improve their products to meet evolving safety standards and regulations. They conduct ongoing research and development to enhance seat belt performance.

-

What happens if a seat belt fails safety testing?

If a seat belt fails safety testing, it cannot be sold to the public until the issues are addressed and it meets safety standards.

View another article here: The 10 Best Neck Knives For Everyday Carry