Head Gasket Repair Guide

For many car owners, head gasket repair can be a significant repair, but it doesn't have to be as frightening as some might imagine. You may effectively identify and fix any issues with the head gaskets in your automobile with careful attention and the appropriate equipment. The fundamentals of head gasket repair will be covered in this blog article, along with potential causes of this problem in cars and advice on how to correctly detect the issue. In order for you to make any necessary plans, we will notify you of the timescales required in diagnosis and repairs. Finally, we will review our recommended procedures for maintenance of these important components in order to prevent future breakdowns or failures. Stay tuned as we explore all there is to know about proper head gasket care and maintenance!

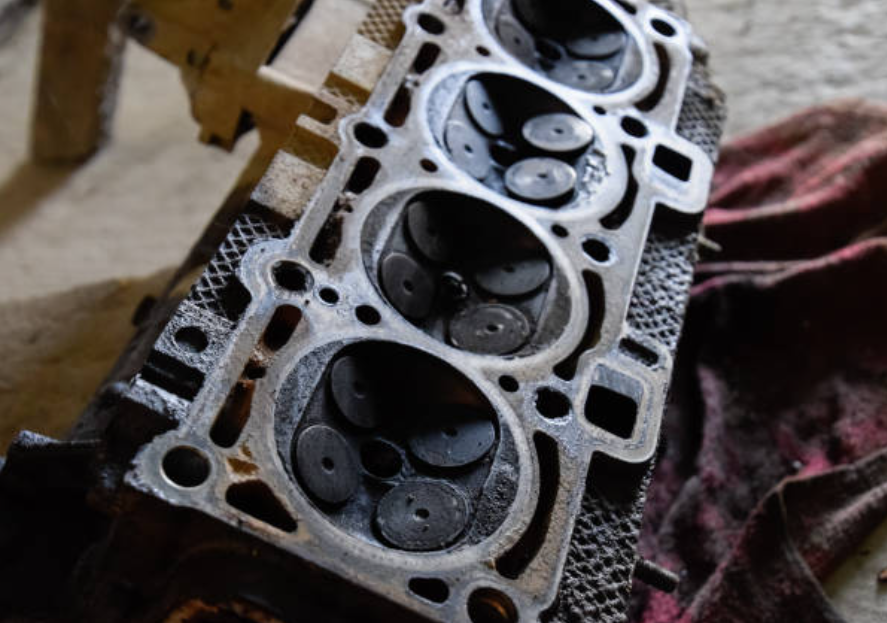

What is a Head Gasket and How Does It Function?

The head gasket is major function is to seal the oil channels, coolant tubes, and combustion chambers to ensure optimum fluid separation and maintain peak engine performance. By preventing the escape of combustion gases, maintaining compression, and directing coolant flow, the head gasket plays a crucial role in the engine's functionality. It must withstand high temperatures and pressure differentials. When a head gasket fails, it can lead to various problems such as coolant leaks, oil leaks, and reduced engine performance. Prompt attention and maintenance are essential to address head gasket issues and preserve the engine's integrity.

A failing head gasket can exhibit several common signs that indicate potential problems within the engine. These signs include engine overheating, the presence of white exhaust smoke, a milky appearance in the engine oil, loss of coolant without visible leaks, engine misfires or poor performance, bubbles in the radiator or coolant overflow tank, and external coolant leaks. Recognizing these symptoms is crucial for diagnosing a failing head gasket and taking prompt action to prevent further damage.

Chemical Sealants: Market-available chemical sealants make a variety of claims regarding their ability to stop head gasket leakage. These sealants are introduced into the cooling system, where they circulate, adhere to the damaged areas of the gasket, and eventually establish an interim seal. Following the manufacturer's instructions to the letter is essential while using these products.

Engine Block Sealer: Another choice for fixing head gasket leaks are engine block sealers. They function by filling in voids and fissures in the gasket material to provide a transient seal. The manufacturer's directions must be properly followed, just like with chemical sealants.

Torqueing the Head Bolts: In rare circumstances, unequal or inadequate torque applied to the head bolts may result in a head gasket leak. If this is the case, using a torque wrench, the bolts can be initially loosened before being tightened in line with the recommended torque sequence. You should only attempt this technique if you are informed and experienced in engine repair.

Engine Disassembly and Gasket Replacement: If the issue is more significant, the engine may need to be disassembled in order to access the head gasket. A replacement gasket must be placed after the cylinder head(s) are removed, the mating surfaces are thoroughly cleaned. It is a time-consuming, difficult process that necessitates a deep grasp of engine mechanics. It is advised that you seek expert help if you lack experience doing this type of repair.

Engine Overhaul or Replacement: In some cases, the damage to the head gasket may be extensive, or there may be additional internal engine issues. In such situations, a complete engine overhaul or replacement may be the most practical solution. This is a significant undertaking and should be performed by a qualified mechanic or engine rebuilding specialist.

To avoid head gasket damage and keep your engine running smoothly, it's important to prioritize regular maintenance. Follow the manufacturer's recommended maintenance schedule, including changing coolant, oil, and filters on time. Monitor coolant levels and temperature to prevent overheating, as excessive heat can strain the head gasket. Use the correct coolant mixture and avoid prolonged high-speed driving or heavy loads in hot conditions. Pay attention to warning signs like white smoke, coolant leaks, or engine misfires, and address them promptly. When performing engine repairs, ensure proper torqueing of head bolts to maintain a secure seal. Finally, avoid putting excessive stress on the engine through aggressive driving or heavy towing. By taking these preventative measures, you can minimize the risk of head gasket damage and maintain the health of your engine.

-

Can I repair a head gasket myself?

Repairing a head gasket is a complex task that requires expertise and specialized tools. While some minor issues may be fixable by experienced DIYers, it's generally recommended to seek professional help to ensure a proper and reliable repair.

-

What happens if I ignore a head gasket problem?

Ignoring a head gasket problem can lead to more severe engine damage over time. It can cause coolant and oil mixing, leading to engine overheating, loss of compression, and potential engine failure. Addressing the issue promptly can save you from more extensive and costly repairs.

See more article here: The 10 Best Car Seat Cushions Of 2023