Discover Dielectric Grease: A Must-Have In Your Garage

While not as essential as oil or coolant, dielectric grease is a popular choice among mechanics nationwide. Typically used on spark plug boots, lightbulbs, and battery terminals, it acts as a protective layer akin to car wax. Though not mandatory, it can extend the life and quality of your vehicle's parts. However, it's important to note that dielectric grease serves a unique purpose and shouldn't be substituted for other lubricants like wheel bearing grease.

Exploring Dielectric Grease: An Overview

Dielectric grease, also known as tune-up grease, serves as a viscous, non-conductive substance essential for safeguarding electrical connections against corrosion and debris buildup.

Primarily formulated with a silicone base and a thickening agent, dielectric grease typically exhibits a slightly translucent appearance, ranging from grayish to milky clear. For instance, Permatex dielectric grease contains key components such as polydimethylsiloxane and silicone dioxide.

Dielectric grease and lubricating grease serve disparate functions, resulting in their distinctive formulations. Unlike dielectric grease, which primarily comprises silicone and a thickener, lubricating grease is a complex blend of lubricating oil, a thickener, and various additives.

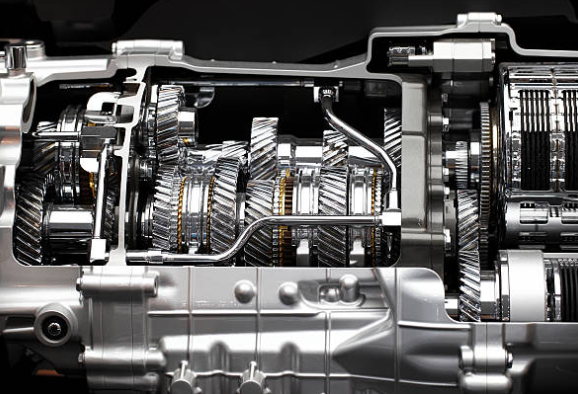

Lubricating grease is specifically engineered to provide lubrication for a wide array of mechanical systems, spanning industrial machinery to automotive components. Its formulation typically integrates lubricating oil sourced from petroleum, vegetable origins, or synthetics alongside performance-enhancing additives and a thickening agent.

In practice, the application of lubricating grease often involves the use of Zerk fittings, small metal male adapters employed to facilitate the precise distribution of grease to the intricate parts of vehicles or machinery.

One prevalent misconception suggests that applying dielectric grease to electrical connections may lead to failure due to the grease interfering with the metal components. However, this notion is unfounded.

Dielectric grease indeed acts as insulation, safeguarding the metal and wiring from external contaminants. Despite this insulating property, the tightness of the contacts ensures that the connection remains intact, with the grease merely displaced. Therefore, contrary to the myth, dielectric grease does not contribute to connection failure.

It's important to note that excessive application of dielectric grease is unnecessary. While it provides valuable protection, there's no need to inundate connectors with excessive amounts, as sometimes depicted in online videos.

- Dielectric grease offers multifaceted benefits when applied judiciously to various components.

- Battery Terminals: Prevent corrosion and ensure optimal conductivity.

- Spark Plug Boots: Enhance electrical insulation and seal against moisture.

- Bulb Sockets: They protect against corrosion and aid in the easy removal of bulbs.

- Trailer connectors guard against corrosion and maintain electrical conductivity.

- General Electrical Connections: Provides insulation and prevents moisture ingress.

- General Plastic or Rubber Lubrication: Lubricates and protects against wear and tear.

- It prevents voltage leakage.

- Insulates in frigid conditions.

- Protects against water damage.

- Guard against corrosion.

- Shields from dirt and grime.

- Resists heat damage.

- Prevents material bonding.

- prevents electrical overheating.

- Ensure the car is parked and cooled down, then open the hood.

- Remove the spark plug boot carefully.

- Clean both the spark plug and the plug boot thoroughly.

- Dispense a small amount of dielectric grease onto a piece of cardboard.

- Using a cotton swab, apply a thin layer of dielectric grease along the inner wall of the spark plug boot.

- Reinstall the plug and boot securely.

- Your application is complete, and your spark plug is ready for optimal performance.

Is dielectric grease essential for vehicle maintenance?

While not as crucial as oil or coolant, dielectric grease protects electrical connections, extending the life of vehicle parts and ensuring optimal performance.

Can dielectric grease harm electrical connections?

No, it insulates without interfering with connections, preserving their integrity and reliability.

How should dielectric grease be applied to spark plug boots?

Clean thoroughly and apply sparingly along the inner boot wall to ensure effective insulation and protection.

Dielectric grease, though optional, safeguards electrical connections, enhancing vehicle longevity and reliability. Its protective properties shield against corrosion and debris buildup, vital for optimal performance. By understanding its application and dispelling myths, integrating dielectric grease into maintenance routines can significantly prolong the life and quality of automotive components, ensuring smooth operation on the road.

Click on the following link to read another blog post: How To Test Ignition Coil?