Direct Injector Seal Service Demystified: Everything You Need to Know?

In the realm of modern automotive maintenance, the landscape is constantly evolving, presenting enthusiasts and mechanics alike with new challenges and opportunities. Direct fuel injection technology stands as a testament to this evolution, offering enhanced performance and efficiency while introducing unique considerations for maintenance. Central to the servicing of direct injection systems are the specialized seals that ensure optimal engine function.

In this guide, we embark on a journey to demystify the process of direct injector seal service, empowering enthusiasts with the knowledge and tools necessary to navigate this essential aspect of contemporary automotive maintenance.

Navigating The Evolution of Automotive Technology

The landscape of affordable used performance cars has transformed significantly over the past decade. With technological advancements reaching new heights, one aspect that stands out is direct fuel injection. While this innovation promises enhanced power, fuel efficiency, and emissions control, servicing components related to direct injection can pose considerable challenges. In particular, the specialized seals utilized in direct injection systems have garnered a reputation for complexity. This guide aims to unravel the intricacies surrounding these seals and provide a comprehensive overview of the replacement process.

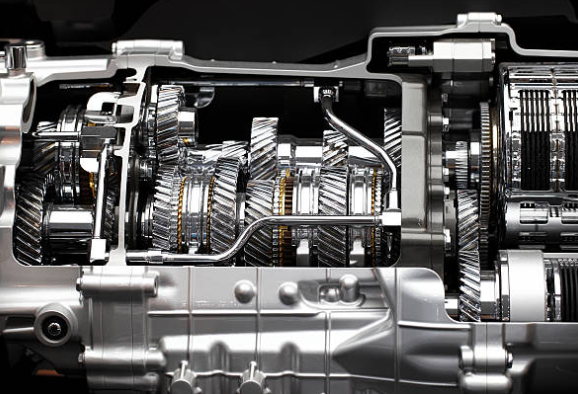

Direct injectors operate under extreme conditions, subject to high temperatures and pressures directly from the combustion chamber. This contrasts starkly with traditional port injectors, which face comparatively lower stresses. The primary function of direct injector seals is to contain the immense pressures generated within the combustion chamber, thereby safeguarding engine performance. Unlike conventional rubber O-rings used in port injectors, direct injector seals must meet stringent demands to prevent compression loss and ensure optimal engine function.

A variety of sealing methods are employed in direct injection systems, each tailored to accommodate specific engine designs and performance requirements. Common approaches include utilizing washers for mechanical sealing and employing nylon seals for smaller injectors. However, the focus here lies on combustion chamber seals, which necessitate meticulous replacement procedures. The process often requires specialized tools or innovative do-it-yourself techniques to ensure precision and efficacy.

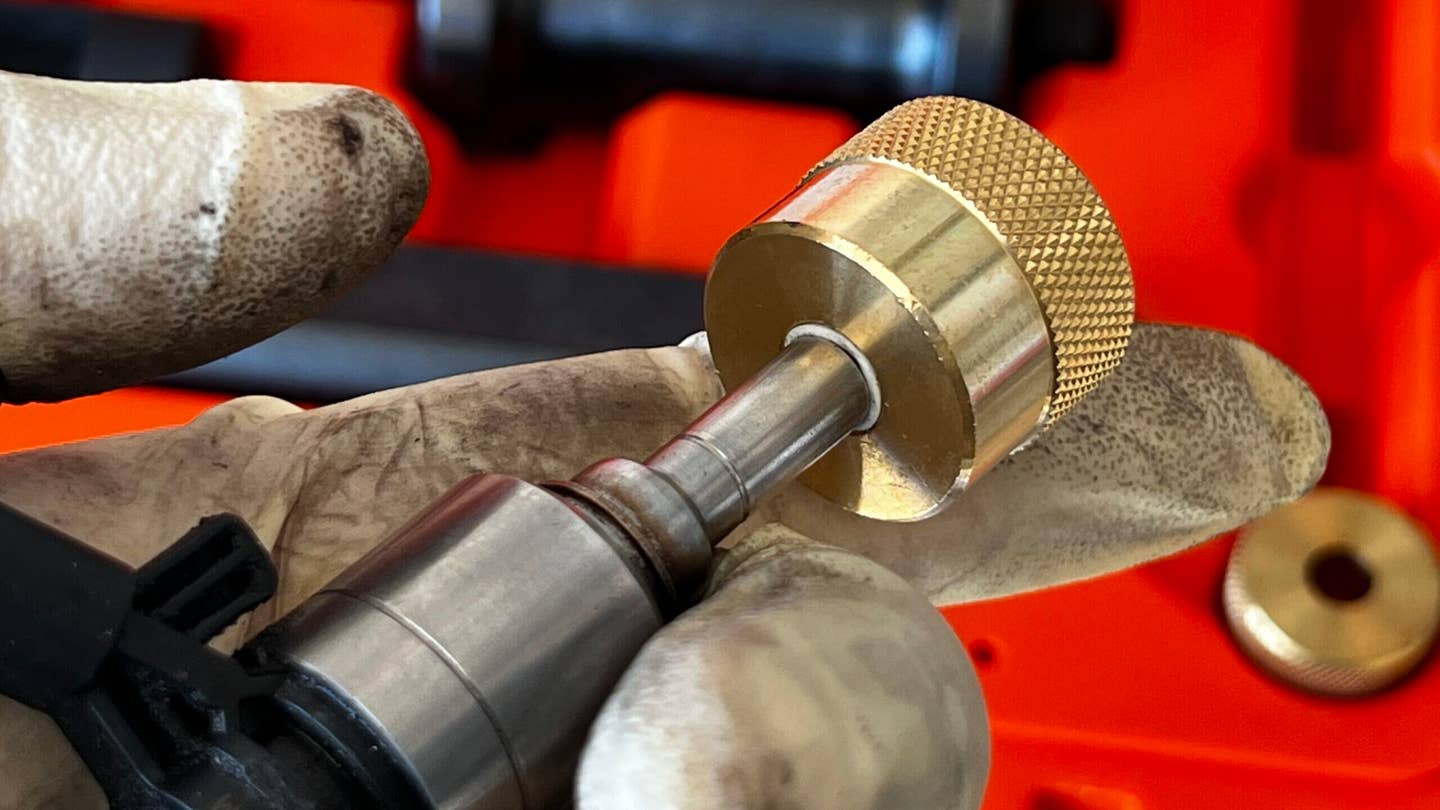

Preparation is key to a successful seal replacement procedure. Acquiring the necessary tools and equipment is essential for streamlining the process and minimizing potential complications. While specific toolkits are available for this purpose, alternative solutions can also be employed, such as those offered by reputable auto parts retailers. These tools not only facilitate the removal and installation of seals but also contribute to the overall efficiency and reliability of the servicing operation.

Replacing direct injector seals demands a methodical approach and careful attention to detail. Beginning with the removal of the old seal, the process involves delicately installing the new seal using specialized tools or improvised alternatives. Achieving the correct seal size is critical to ensuring a snug fit and effective sealing within the combustion chamber.

In addition to traditional methods, alternative techniques offer viable options for seal replacement in direct injection systems. The overnight zip-tie method, for instance, provides a practical solution in the absence of specialized tools. By leveraging readily available household items, enthusiasts can adapt and innovate, ensuring that seal replacement remains accessible and achievable.

Upon completing the replacement procedure, reinstalling the injectors and conducting thorough testing are essential steps in verifying the efficacy of the service. A meticulously executed replacement should result in a smooth-running engine, free from irregularities or performance issues. This validation process instills confidence in the reliability and longevity of the newly replaced seals.

By demystifying the complexities associated with direct injector seal replacement, this guide empowers automotive enthusiasts to tackle servicing tasks with confidence and competence. Through careful preparation, precise execution, and a commitment to innovation, maintaining peak engine performance becomes an achievable endeavor for all enthusiasts.

Why are direct injector seals necessary?

Direct injector seals contain high temperatures and pressures in direct injection systems, ensuring optimal engine performance.

What are the consequences of neglecting seal replacement?

Neglecting seal replacement can cause compression loss, reducing engine performance and efficiency. Leaks may compromise combustion integrity, causing potential long-term damage.

Are specific tools required, and where can they be obtained?

Specialized toolkits or household items suffice. Auto parts retailers may offer rental services, providing necessary equipment access without significant cost.

Can seals be reused?

While guidelines recommend replacement, properly maintained seals can be reused, though careful inspection is essential.

This guide equips enthusiasts with the knowledge needed to maintain modern automotive systems effectively. Whether using specialized toolkits or DIY solutions, enthusiasts can approach seal replacement confidently for optimal engine performance and longevity. Let's embrace the challenges ahead, armed with understanding and determination to keep our engines running smoothly.

Click on the following link to read another blog post: Why Does My Car Smell Funny? Lets Explore